|

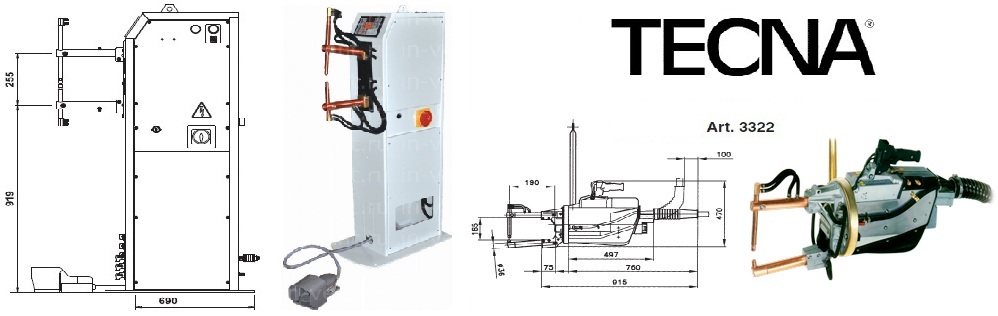

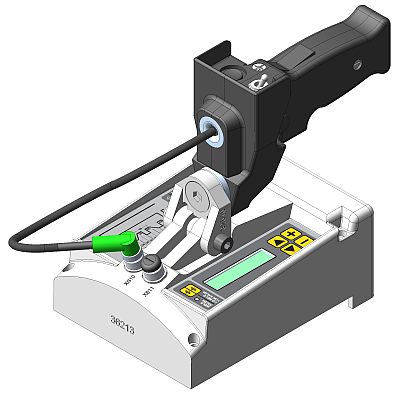

TE 470

|

|

|

|

MAIN

FEATURES

-

Simplified

programming

by means

of 5

push-buttons

and LCD

alphanumeric

display.

-

Controlled-diodes

synchronous

drive

with

phase

shift

control

for

welding

current

adjustment.

- 63

welding

programs

to be

stored

up; 2

programs

can be

recalled

from the

handle.

- 19

programmable

parameters

or more

for each

program.

-

Slope

and

pulse

functions;

pre-weld

and

post-weld

functions.

-

Welding

times

adjustment

in half-periods.

-

Display

of both

welding

current

in kA,

and

connected

conduction

angle.

-

Working

modes:

FIX,

PW%,IK,

ENERGY.

-

Either

welding

current

or

conductor

angle

limits.

-

Automatic

double

stroke

function

(to be

employed

only

when the

welder

has been

designed

for this

function).

-

Three

working

modes

along

the

machines

stroke:

SHORT,

LONG,

AUTO.

-

Stepper

function

to

balance

the

electrodes

wear-out

with

adjustable

curve.

-

Welds

counter.

-

Programming

key-lock.

-

Single

and

automatic

cycle.

WELD/NO

WELD

function.

-

Delay of

first

phase

shift

adjustment

to get

the bet

balance

of the

machine

absorption

from the

mains.

-

Control

of 2

solenoid

valves

24 Vdc

7,2 W

Max with

protected

output

against

short

circuit:

electrodes

closing

valves

and

double

stroke

valve.

-

Self-adjustment

to the

mains

frequency

50/60

Hz.

- Data

communication

with

field

bus

(RS232,

RS485)

-

Minimal

I/O for

interfacing

with

plcs and

safety

systems.

-

Calculation

and

check-up

of the

thermal

current

with

alarm

signal.

|

|